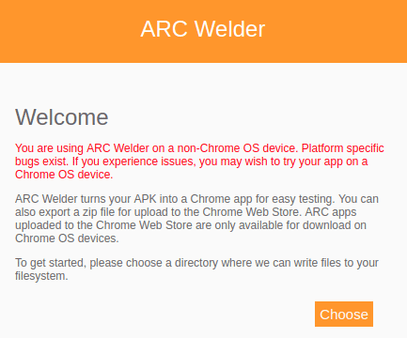

I am dairly new to printing, but digging in and trying to learn as much as I can. Any experiences or explainations would be appreciated. Is gcode streamlined enough to make up for increased frontend processing? Do I only need to worry about it if running 10k+ accel?ģ) if the calculations are being made to the gcode, not the slicer with the original model, does this affect dimensional accuracy? If it doesn't know what the final object is supposed to look like, how can it be sure to follow? Will in round off intentionally sharp edges or ridges? Blend in some detail?įigured this was the best community to ask for info on this plug-in. I use Fluidd, and heard Octoprint was bloated and used tons of resources, which has caused people issues on some faster printers. Will it make a difference?Ģ) Seems tied to Octoprint. It xan handle exponentially more instructions than an 8bit mcu. I have an SKR2 with Pi3b+ running Klipper. My hesitancy with using it areġ) Seems the primary benefit is that it reduces instruction to the printer, which is very beneficial with 8bit boards. Seems to me, most objects can easily be defined as lines and arcs, so that makes sense. Convert lines into arcs after the slicer is done with file. (Fillet weld/lap joint 0.7-0.8mm and above) (Docking/T type 1.0mm and above) 1.0-6mm stainless steel (Fillet weld/lap 1.2mm and above) (Docking/T type 1.5mm and above) 1.I have been hearing a lot about Arc Welder. l Built-in positioning function: no need to add positioning hardware.

L Optional fish scale welding function: there is a dimensional arc to reduce spatter when interrupted and speed is increasing at the same time. L Wire feeder encoder feedback control: it can be adjusted quickly when the arc fluctuates. L Very high clearance tolerance: high clearance tolerance for errors in workpiece sets. L Smooth short-circuit transition: the arc is softer, tensed, and the shape is more beautiful. L Thin plate technology with low heat control: stable arc at very low voltage. L The robot and the welder communicate with each other through all-digital communication, which is fast and stable.īoth CO2 and mixed gas can be welded with ultra-low spatter: l Thin plate technology in the arc welding software package: small line segment acceleration, flying arc starting to improve the beat effectively, welding wire withdrawal function effectively improves the arc starting success rate, fish scale welding can weld thinner plates. L The robot moves fastly, improves the beat effectively, processes naturally.

0 kommentar(er)

0 kommentar(er)